Next Gen Washing Machine & Dryer

Designing the Human Machine Interface (HMI) for a new-to-market, dual-basket premium washer and dryer system

Role: Principal UX Designer

Year: 2025

Product Type: Embedded / HMI / Physical HMI

Context & Problem Framing

Whirlpool operates in a highly competitive appliance market where meaningful differentiation is increasingly difficult. To differentiate and regain leadership in the premium segment of appliances, the team developed a completely new-to-market dual-basket washer, which enables delicates and regular clothes to be washed at the same time, leading to a reduction in time, energy use, and cognitive effort.

Product Goals:

Reduce total wash time

Lower water and energy usage

Decreased mental overhead for users managing multiple loads

The Question

How do you make a fundamentally new physical capability feel intuitive, trustworthy, and immediately usable, without disrupting deeply ingrained mental models around home laundry?

UX Requirements

Existing technology/engineering panel

Add new function into existing HMI

Don’t disrupt users existing and deep mental model of clothes washing

The Approach

The Human-Machine Interface (HMI) became the primary lever for bridging this gap, not only responsible for control, but for education, motivation, and confidence-building during first-time and repeat user.

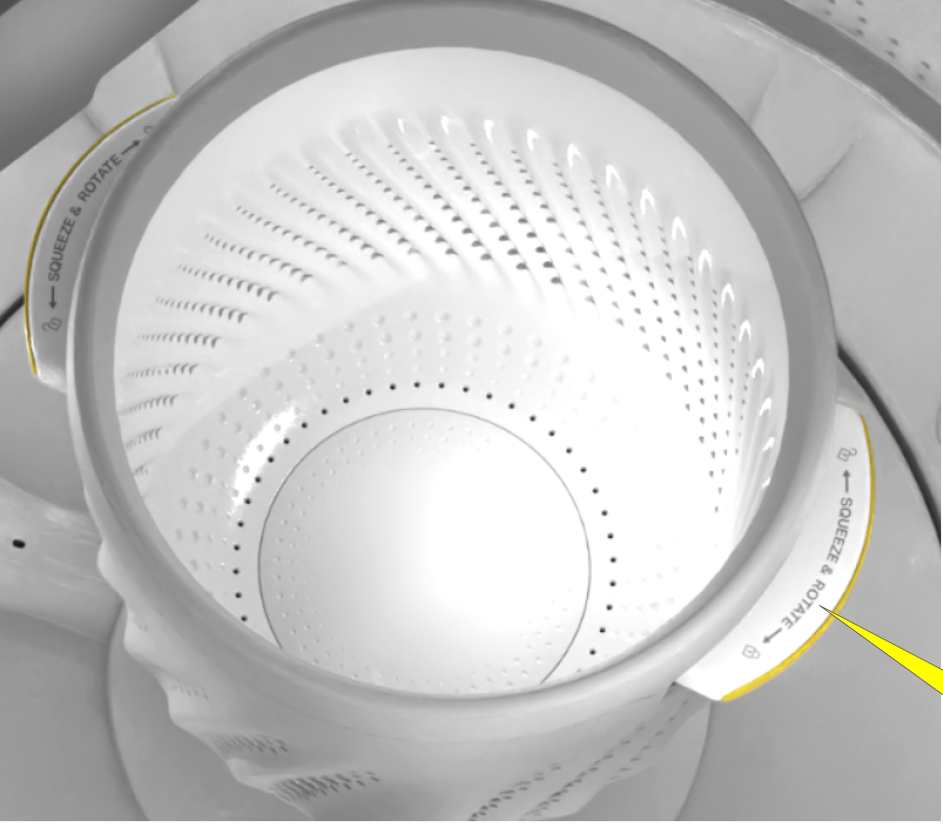

The image on the left portrays the delicate basket placed within the regular drum of the washing machine.

My Role

I led UX Strategy and interaction design for the washer and dryer HMI, working within a tight, cross-functional team of industrail designers, mechanical and software engineers, and marketing partners.

I was responsible for:

ADD IMAGES OF RESPONIBILITIES?

I was responsible for:

End-to-end UX strategy for the HMI

User research planning and synthesis

Journey mapping and scenario definition

User flow and interaction models

Information architecture and control logic

Defining scalable interaction patterns and component behaviors

I collaborated closely on

Functional requirements and technical feasibility

Visual language alignment with brand and graphics teams

Engineering constraints, validation rules, and safety considerations

This work spanned concept through detailed design and specification, an

Constraints & Realities

Legacy engineering architecture: The HMI was built on an existing control platform, limiting flexibility in input types, system states, and responsiveness.

Regulatory and safety requirements: Specific interaction rules, e.g. button hold durations, lovk behaviors, were mandated to prevent unsafe use (child safety and accidental activation)

Multi-brand considerations: The solution needed to scale across Whirlpool and Maytag, requiring subtle brand differentiation without fragementing the core interaction model

Technical debt and late-stage validation: Early Industrial Design assumptions had not been fully stress-tested, requiring UX to reconcile usability issues later in the process without expanding scope or timelines.

Stakeholder misalignement: Marketing priorities around feature visibility occasionally conflicted with UX goals of clarity and cognitive simplicity

Limiting sensing and feedback technology: The machine could not “know” what users asumed it would, requiring careful expectation-setting through the interface

These constraints made it clear that success would depend less on visual polish, and more on clear system logic and interaction discipline.

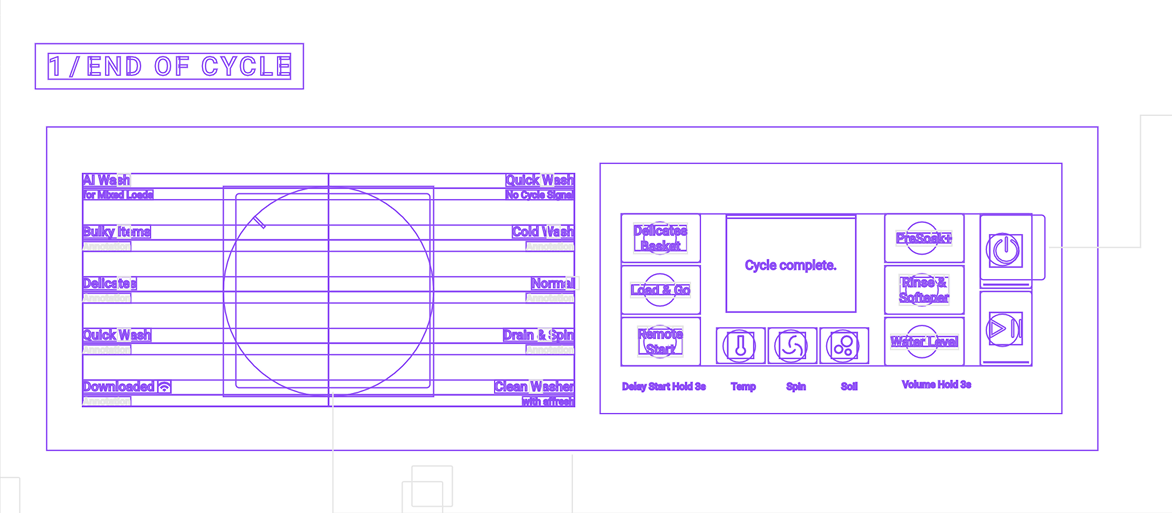

Behind each Human Machine Interface that the user sees is hardware and specifically placed technologi

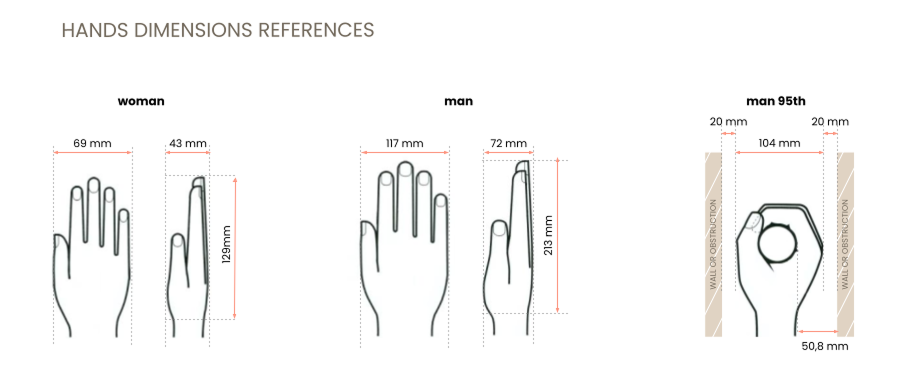

These are the dimensions of hands that we design buttons, handles, and screens to

Discovery & Insights

Early assumptions suggested that the dual-basket functionality could be introduced via a single new control on the HMI. However, when we mapped real user scenarios across the laundry lifecycle, from load planning to cycle completion, this approach quickly broke down.

Through journey mapping, user flow exploration, internal and secondary research, and system modeling we uncovered several critical insights.

Critical Insights:

Laundry is a habitual, low-attention activity - users rely heavily on muscle memory and pattern recognition

Introducing choice at the wrong moment increases hesitation and error, more than empowerment

Users need reassurance that the emachine was “doing the thing right” especially when two loads behaved differently within a single cycle.

Transitions between setup, active wash, and completion were the moment of highest confusion and opportunity.

The insight was not that users needed more control, but that they needed better timing, clearer feedback, and reduced deciision making burden.

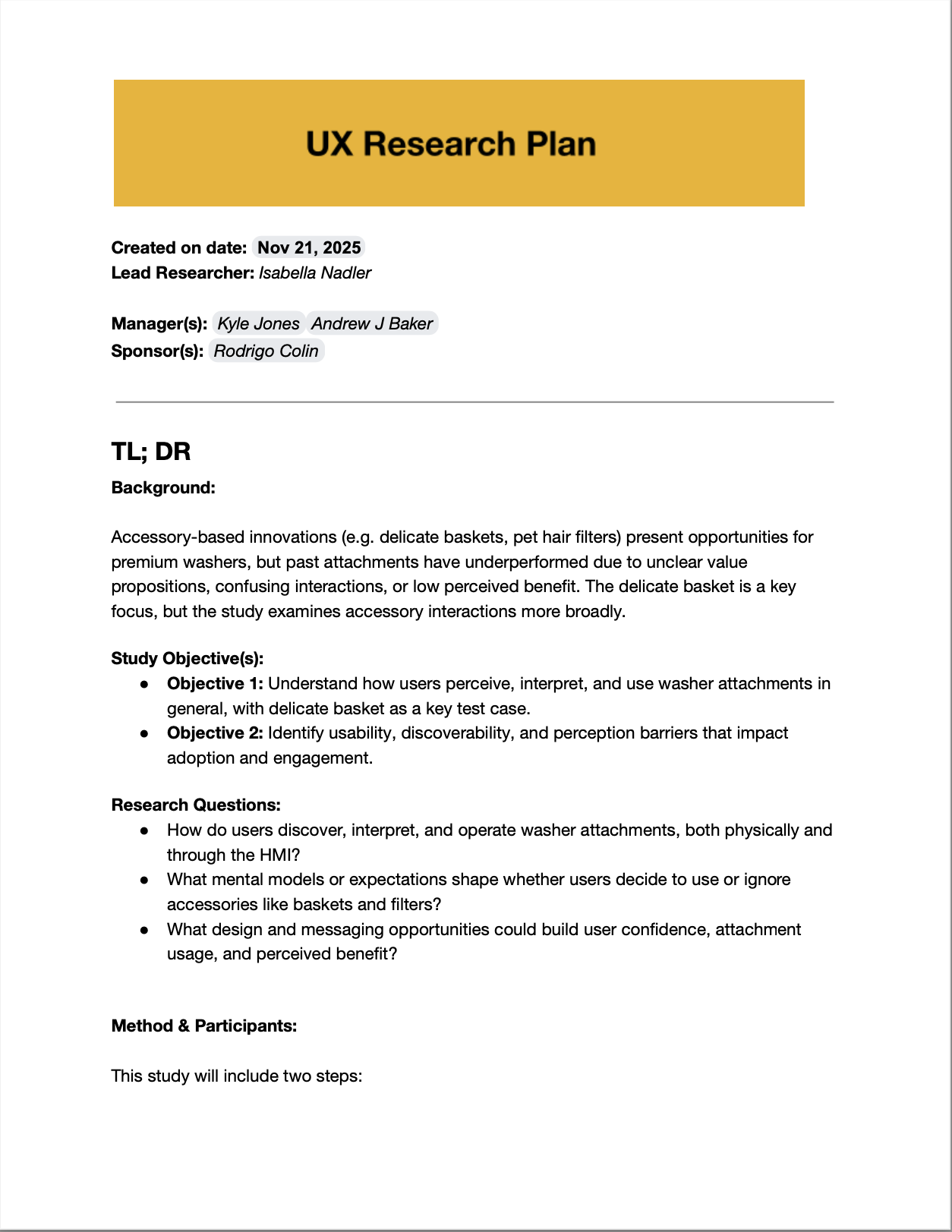

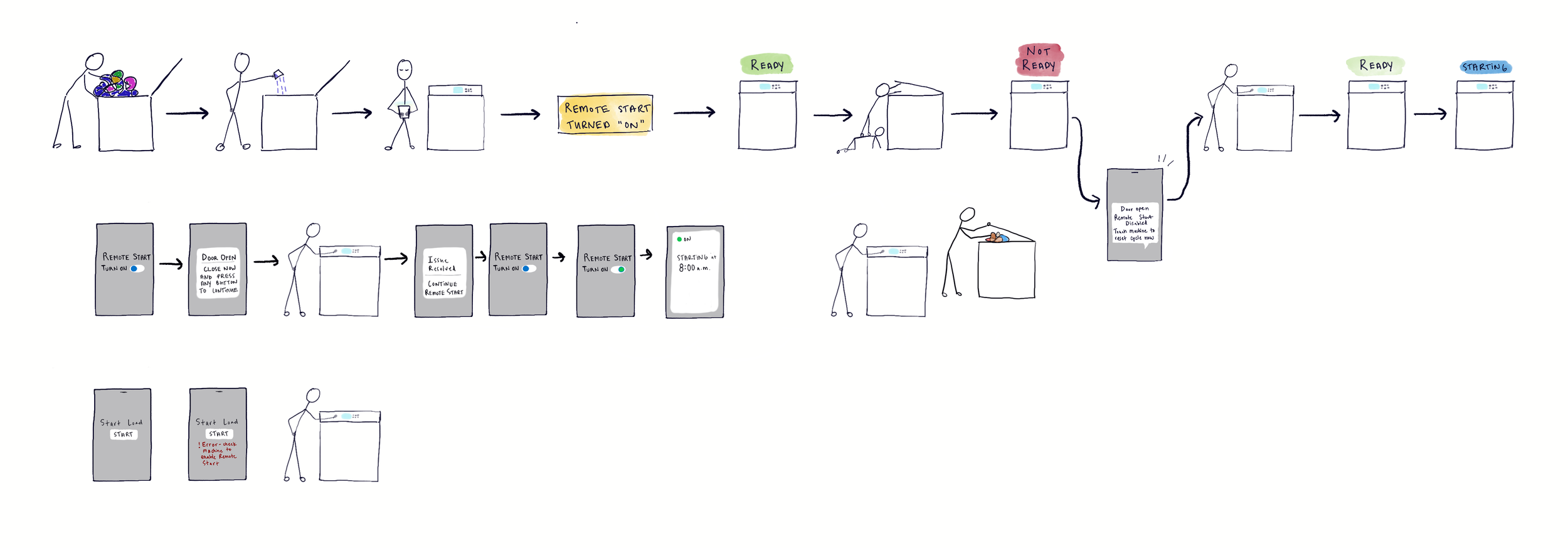

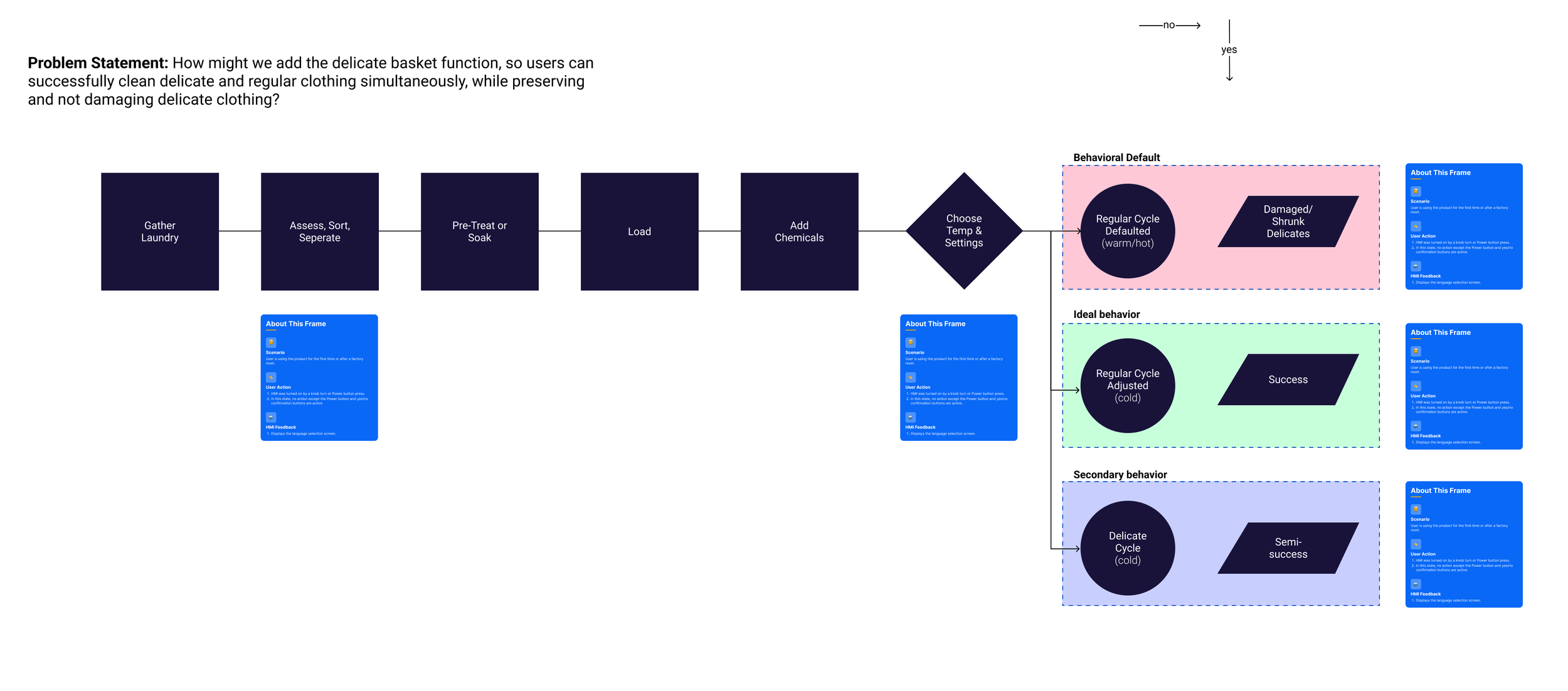

Quick early sketch to map out high-level process of washing laundry, ensuring alignment between teams before moving into interaction design

Further analysis on the potential outcomes from our hypothesized user steps

Design Strategy

Initial assumptions suggested the feature could be introduced with a single HMI control. However, scenario mapping revealed the interaction was more complex, requiring a deeper dive into the flow to ensure we were could support real-world use.

Our strategy focused on three priorities:

• Making the new capability intuitive through contextual guidance and progressive disclosure

• Reducing cognitive load by automating or clearly signaling key transitions

• Designing scalable interaction patterns to support future products

Execution

During the design execution phase phase, I focused on translating the strategy into a robust, testable interaction system

Early concepts explored multiple mental models for dual-basket washers, included system-led automation, parallel clows, master-secondary relationship

Iterative Refinement narrowed the solution to a model that balanced established system hardware with user agency

Detailed flows and specs defined edge cases, validation rules, and feedback states

Component definitions ensured consistency across waher and dryer interfaces while allowing brand-level differentiation

Rather than optimizing individual screens, the work prioritized flow integrity across time - from first interaction to cycle completion.